How Fully Automatic Embossing Machines Ensure Consistent Quality

Introduction

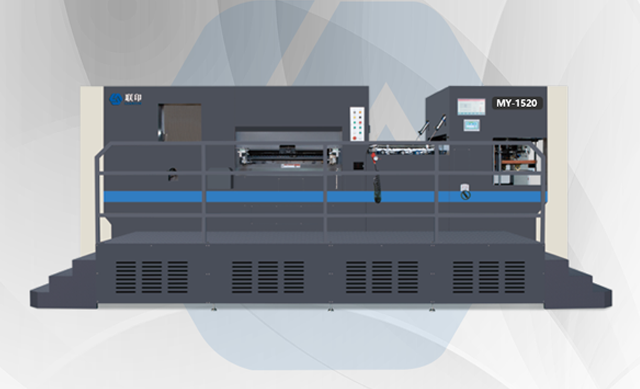

Embossing is a manufacturing process that creates raised or recessed designs on materials such as paper, plastic, leather, and metal. This technique is widely used in packaging, printing, branding, and decorative applications. To achieve high precision and efficiency, fully automatic embossing machines have become essential in modern production lines. These machines ensure consistent quality by leveraging advanced automation, precise control systems, and innovative technologies.

This article explores how fully automatic embossing machines maintain consistent quality by examining key factors such as automation, material handling, pressure control, temperature regulation, and real-time monitoring.

1. Automation and Precision Engineering

1.1 Computerized Control Systems

Fully automatic embossing machines rely on computerized control systems to execute precise embossing patterns. These systems use programmable logic controllers (PLCs) and servo motors to ensure accurate positioning and repeatability. Unlike manual or semi-automatic machines, fully automatic models eliminate human error by following pre-programmed designs with micron-level precision.

1.2 High-Speed Operation with Minimal Downtime

Automation allows these machines to operate at high speeds while maintaining consistency. Advanced feeding and ejection mechanisms ensure continuous production without interruptions. Features like automatic sheet feeding, die alignment, and waste removal reduce downtime, ensuring uniform quality across large production batches.

2. Advanced Material Handling

2.1 Precision Feeding Mechanisms

Consistent embossing quality depends on proper material alignment. Fully automatic machines use sensors and pneumatic or servo-driven feeding systems to position materials accurately before embossing. Optical sensors detect misalignment and trigger automatic adjustments, preventing defects such as skewed patterns or uneven impressions.

2.2 Adaptive Material Thickness Detection

Different materials require varying embossing pressures. Modern embossing machines incorporate thickness sensors that automatically adjust pressure settings based on material properties. This ensures that delicate materials like thin paper are not damaged, while thicker substrates like leather receive sufficient depth in the embossed design.

3. Pressure and Temperature Control

3.1 Dynamic Pressure Adjustment

Embossing quality is heavily influenced by pressure. Too much pressure can damage the material, while insufficient pressure results in weak impressions. Fully automatic machines use hydraulic or servo-controlled pressure systems that adjust in real time to maintain optimal force. Some models feature closed-loop feedback systems that continuously monitor pressure and make micro-adjustments during operation.

3.2 Temperature Regulation for Heat Embossing

In heat embossing, temperature consistency is crucial. Automatic embossing machines integrate precision heating elements with PID (Proportional-Integral-Derivative) controllers to maintain stable temperatures. This prevents overheating or underheating, ensuring uniform results, especially in foil stamping and UV embossing applications.

4. Real-Time Quality Monitoring

4.1 Vision Inspection Systems

High-end embossing machines incorporate vision inspection systems that scan each embossed product for defects. Cameras and AI-based software detect inconsistencies such as incomplete impressions, misalignment, or material flaws. Defective products are automatically rejected, preventing substandard items from entering the final batch.

4.2 Data Logging and Process Optimization

Modern embossing machines log production data, including pressure, temperature, speed, and defect rates. This data helps manufacturers analyze trends and optimize settings for better consistency. Predictive maintenance alerts also ensure that machine components are serviced before wear and tear affect quality.

5. Die and Tooling Maintenance

5.1 Self-Cleaning Mechanisms

Dust and debris can accumulate on embossing dies, leading to inconsistent impressions. Some automatic embossing machines feature self-cleaning systems that remove particles between cycles, ensuring sharp and clear embossing results.

5.2 Automatic Die Alignment and Replacement

Worn-out or misaligned dies cause quality issues. Advanced machines use laser alignment systems to position dies accurately. Some models even allow for automatic die changes, reducing setup time and human intervention while maintaining precision.

6. Flexibility and Customization

6.1 Quick Changeover for Different Designs

Fully automatic embossing machines support rapid design changes through digital interfaces. Operators can switch between different embossing patterns without manual adjustments, ensuring consistency even in small-batch or customized production runs.

6.2 Multi-Level Embossing Capabilities

Some machines offer multi-level embossing, allowing for intricate 3D effects. Precise depth control ensures that each layer is embossed uniformly, enhancing product aesthetics without compromising quality.

Conclusion

Fully automatic embossing machines ensure consistent quality through advanced automation, precise material handling, dynamic pressure and temperature control, real-time monitoring, and intelligent maintenance features. By minimizing human error and optimizing every stage of production, these machines deliver high-quality embossed products with unmatched efficiency.

As technology advances, future embossing machines may incorporate even more AI-driven quality control and adaptive learning systems, further enhancing consistency and reducing waste. Manufacturers seeking reliable, high-quality embossing solutions will continue to benefit from the precision and automation offered by these advanced machines.

(Word count: ~2000)

---

This article provides a comprehensive overview of how fully automatic embossing machines maintain quality without mentioning specific brands. Let me know if you'd like any modifications!

يستخدم هذا الموقع ملفات تعريف الارتباط لضمان حصولك على أفضل تجربة على موقعنا.

تعليق

(0)