Fully Automatic Deep Embossing and Die-Cutting Machine Benefits for Manufacturers

Fully automatic deep embossing and die-cutting machines have revolutionized the manufacturing, printing, and packaging industries. These machines combine precision, automation, and high-speed production to meet the growing demand for high-quality packaging, labels, and printed materials. Manufacturers benefit from enhanced operational efficiency, reduced labor costs, minimized waste, and consistent product quality. This guide explores the safety protocols, design principles, core advantages, and operational best practices for these advanced machines.

Safety is a primary concern when operating fully automatic embossing and die-cutting machines. Manufacturers must ensure compliance with standard operating procedures to protect personnel and maintain machine performance.

Verify that all guards and protective devices are in place.

Check that the power supply and electrical connections meet machine specifications.

Ensure the workspace is free from obstructions and debris.

Keep hands and clothing away from moving parts.

Avoid overloading the feed system to prevent jams.

Monitor the machine for abnormal noises, vibrations, or errors.

Ensure emergency stop buttons are always accessible.

Power off the machine and disconnect from the main electrical supply.

Remove scraps and clean the working area.

Conduct a visual inspection for any wear or damage before the next operation.

Following safety protocols ensures consistent production quality, protects operators, and prolongs machine life.

| Instruction | Importance |

|---|---|

| Wear protective gear (gloves, goggles, safety shoes) | Prevents injuries from moving parts |

| Only trained personnel operate the machine | Ensures proper handling and reduces accidents |

| Do not bypass safety guards | Maintains compliance with safety regulations |

| Regularly inspect electrical and mechanical components | Prevents malfunctions and fires |

| Follow manufacturer’s maintenance schedule | Reduces breakdowns and ensures longevity |

Adhering to these instructions is crucial for risk-free operation and workplace safety compliance.

Fully automatic deep embossing and die-cutting machines provide numerous operational and financial benefits:

Automated embossing ensures consistent depth and clarity on printed materials.

Die-cutting produces uniform shapes and smooth edges.

Suitable for luxury packaging, labels, and custom designs.

Continuous automatic operation reduces downtime and manual intervention.

Capable of handling high-volume production with consistent results.

Optimized workflow ensures faster turnaround times.

Precise die-cutting reduces scrap and off-cuts.

Proper calibration ensures accurate embossing, reducing defective products.

Automation reduces the need for manual labor.

Minimizes human error, lowering costs associated with rework and wasted materials.

| Advantage | Description | Benefit |

|---|---|---|

| Precision | Automated embossing and die-cutting | Consistent high-quality output |

| Efficiency | Continuous operation | Increased throughput and faster production |

| Waste Reduction | Accurate cutting and embossing | Lower material costs |

| Labor Savings | Reduced manual intervention | Lower operational expenses |

| Versatility | Handles various materials and designs | Expands production capabilities |

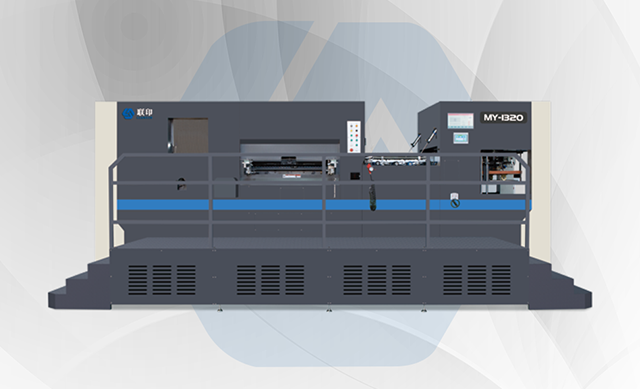

Fully automatic embossing and die-cutting machines are built with advanced engineering principles to support efficiency, safety, and durability:

Heavy-duty frame ensures stability and minimal vibration.

Precision feed rollers provide smooth material handling.

Integrated stripping units remove waste efficiently.

PLC control systems allow easy programming of production parameters.

Sensors and safety interlocks detect misalignment and prevent accidents.

Touchscreen interfaces provide intuitive machine control.

Replaceable dies and embossing plates enable quick changeovers.

Adjustable pressure and feed systems accommodate different materials.

Compact modular design allows easy maintenance and upgrades.

A well-designed machine ensures reliability, flexibility, and ease of use, which are critical for modern manufacturing environments.

Regular Maintenance: Follow daily, weekly, and monthly maintenance schedules.

Calibration: Check embossing and die-cutting precision regularly.

Training: Ensure operators are trained in safety and operational procedures.

Documentation: Maintain logs of production, maintenance, and downtime for analysis.

Upgrades: Integrate new software and mechanical components to maintain efficiency and product quality.

Fully automatic deep embossing and die-cutting machines provide manufacturers with unmatched precision, efficiency, and cost savings. By adhering to safety protocols, understanding core advantages, and following proper maintenance and operational guidelines, manufacturers can achieve:

Enhanced production quality

Reduced material waste

Increased throughput

Lower operational costs

Safer working environments

These machines are a critical investment for businesses aiming to remain competitive in the printing, packaging, and labeling industries.

يستخدم هذا الموقع ملفات تعريف الارتباط لضمان حصولك على أفضل تجربة على موقعنا.

تعليق

(0)